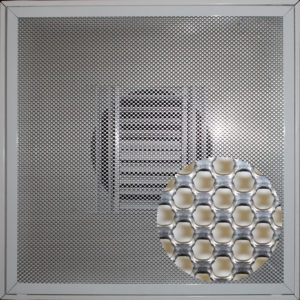

Commercial HVAC systems typically include a perforated vent diffuser grille. Wallner Expac offers an alternative that looks like perforated metal but has all the advantages of expanded metal: Perfex.

Perfex, our Product Spotlight for this quarter is not your traditional diamond-shaped expanded metal. With an innovative design and using a precision manufacturing process that does not punch the metal, Wallner Expac can produce expanded metal with an aesthetic circle finish.

WHY USE PERFEX AS DIFFUSER GRILLES?

Structural Stability and Pattern Uniformity

A key advantage of expanded metal over perforated is how it is manufactured. Using Wallner Expac’s Shear-Form® service of manufacturing, the metal is slit and simultaneously stretched instead of punching holes in it. This yields a high strength-to-weight ratio with pattern uniformity. Perfex is designed to allow maximum air circulation, leading to increased indoor air quality and efficient HVAC operations.

Less is More!

By slitting and stretching, the expanded metal process conserves material by providing a greater yield in finish product to raw. A typical yield of finished to raw product is 3:1 and often significantly more depending how much the metal is stretched.

Manufactured in the USA

As with all expanded metals from Wallner Expac, Perfex is manufactured to customer specifications in its California and Georgia facilities. It can be expanded in widths up to 48”, flattened, and even painted or powder coated. This combination of strength and aesthetics makes Perfex a great choice for applications such gates and fencing, pet guards, ceiling panels, partitions, and of course vent mesh for diffuser grilles.

Wallner Expac has over 50 decorative and standard expanded metal patterns- including our patented X-Mesh® and MicroForm™, all tunable to meet your needs. Should a new pattern need to be created, Wallner Expac’s on-site design and engineering team is available for collaboration. For a turnkey solution, our on-site tooling facility offers post-production metal forming services include flattening, stamping, surface grinding, Wire EDM, CNC machining, and more.

For more information including sample requests, please contact Manuel Menchaca, Sr. Marketing Manager at mmenchaca@expac.com or (909) 736-4894.

back to all news