ONTARIO, Calif. – July 25, 2019 – Manufacturer and designer of expanded metal Wallner Expac broadens its product line with the addition MicroForm®– its line of precision engineered expanded metals for use in specialized applications.

ONTARIO, Calif. – July 25, 2019 – Manufacturer and designer of expanded metal Wallner Expac broadens its product line with the addition MicroForm®– its line of precision engineered expanded metals for use in specialized applications.

Responsible for the management, development, and implementation of MicroForm®, Sean Flora, MSME, Sr. Mechanical Design Engineer, Wallner Expac shares his thoughts: “After extensive design and development our team is proud to introduce MicroForm®. This new product offering has unique properties which afford us the opportunity to enter new markets and expand our corporate footprint. Accomplishing this required the combination of technical innovation and experience gained from decades of expanded metal manufacturing.”

Manufactured in Wallner Expac’s new climate-controlled environment, MicroForm® can be manufactured into light- and heavy gauge variants using common and exotic metals. Tight tolerances allow production capabilities to expand the LWDs from 0.125” down to 0.050” using materials with a minimum thickness of 0.002”. Post-production services include flattening, slitting, cut-to-length, stamping and more.

Mariana Orozco, President, Wallner Expac adds, “It’s always exciting to see a concept or idea brought to fruition. Being a part of the entire development process was both exciting and a valuable learning experience for myself as well as our whole team. The team leveraged its many years of experience to optimize our operations for the production of MicroForm®. Each and every employee played an intricate role in the creation and introduction of MicroForm® including the manufacturing of all the required equipment and tooling that was designed and fabricated in our state-of-the-art on-site tool room, and we couldn’t be any prouder of how our staff performed.”

Specialized uses for MicroForm® include:

Battery Technologies- Support Foils

Contrary to popular belief, it is the substrates– which are primarily composed of a paste or powder– that make up the electrically active material. These substrates are applied to a thin metal support foil that is wound or folded to provide a continuous layer. The electrolytes are formed from these substrates which are applied as a thin layer on current collector foils, such as aluminum for the cathode side and copper for the anode side.

EMI/RFI Shielding

When properly integrated into sensitive electronics, it can effectively suppress interference or unwanted frequency signals in aerospace, telecommunications, automotive, or other mission-critical systems.

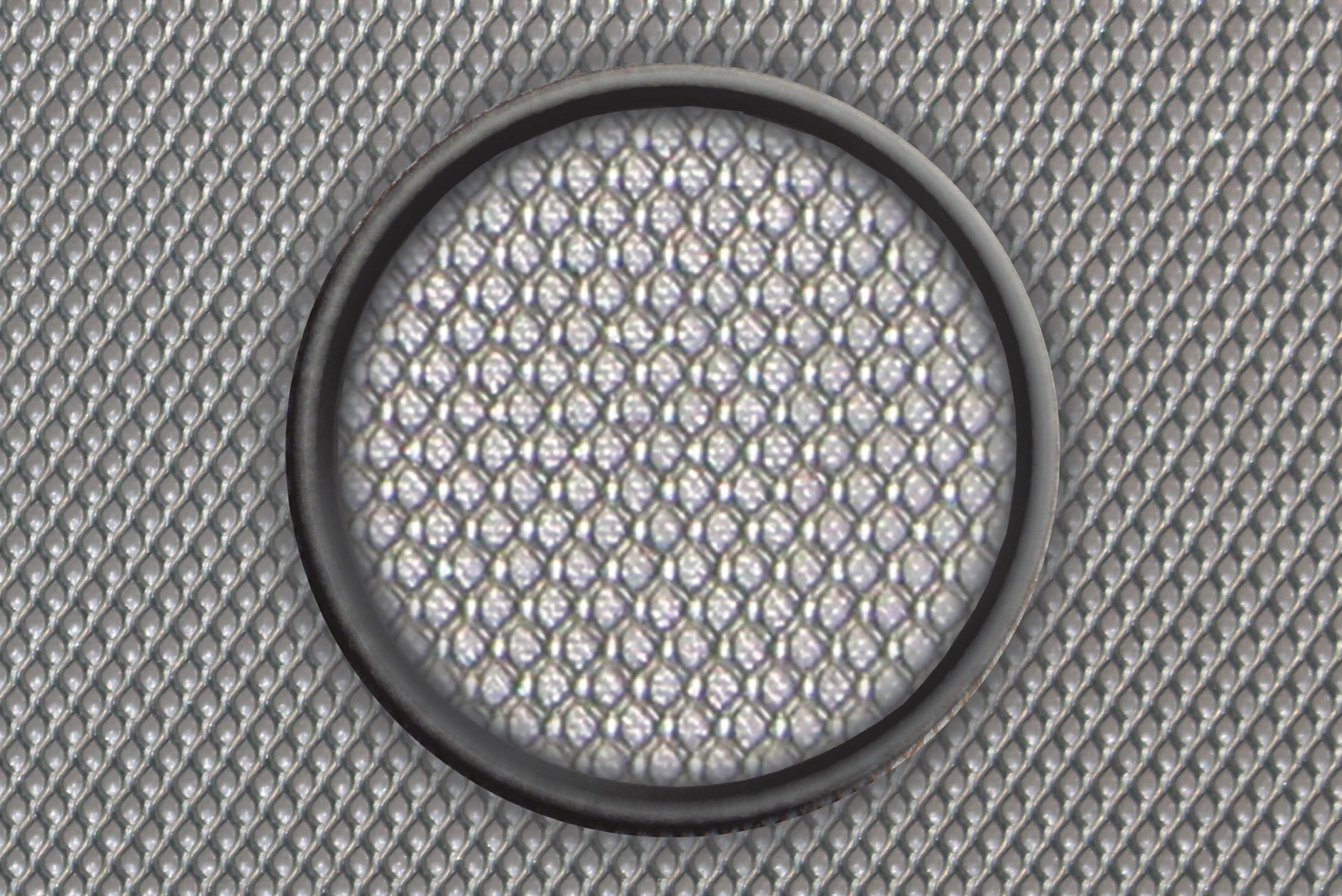

Microfiltration

Our ability to precisely adjust the openings– including open area percentage allow its use for gaseous, solid, or liquid filtration applications.

Equally versatile for decorative applications, heavy gauge MicroForm® can be used for speaker grilles, shading, window and door screens, and more.

Additionally, the brand MicroForm® has been granted a registered trademark by the U.S. Patent & Trademark Office.

A dedicated MicroForm® web page and info sheet are now available with more literature forthcoming. For more information or samples, please contact Manuel Menchaca, Sr. Marketing Manager, Wallner Expac.

back to all news